Whilst 3D Printing has many benefits in R&D for creating prototypes, 3D printers can also play a key role in manufacturing technology.

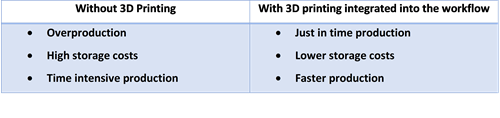

Currently the spare parts industry struggles typically with overproduction and high costs for storage and logistics. It is estimated that within 5 years, 85% of the spare parts industry will use 3D printing in their workflow to address some of these common challenges. (Source: AMFG- How 3D Printing is Transforming the Spare Parts Industry)

3D Printing - Positive Transformations

3D technology provides many opportunities for the spare parts industry to improve efficiencies in the following ways:

Source: EOS- Efficient Spare Parts Logistics with Additive Manufacturing

By using 3D printers in the workflow, manufacturers will have far greater flexibility and agility in the manufacturing process, cutting out intensive production and reducing overall costs.

Sector in Focus – Automotive Sector

The automotive industry has been one of the early adopters of 3D Printing technology. Initially this technology was used mainly to produce prototypes in the automotive space. In 2018, automotive companies began to research the potential of additive manufacturing in the production of spare parts. Daimler AG and the Volkswagen Group are two such examples of early adopters. The benefits are manifold:

- cost-effective production,

- higher sustainability,

- rapid response to feedback and

- flexible adaptation.

Source: LEAD -How the automotive industry plans to use 3D printing to create new business models

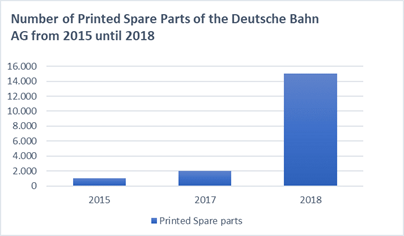

The automotive sector is not alone in its adoption of 3D printing. Deutsche Bahn AG utilises 3D printers in their workflow and the number of printed spare parts has risen rapidly.

Source: Statista

Challenges of 3D printing for Spare Parts

The integration of 3D printing for spare parts is not without its challenges. One challenge is the question of process repeatability. The concern is that quality may be diluted after the first few process repetitions. Therefore, quality standards must be set for the process at the onset to ensure that compliance is met.

In Addition, there are legal barriers, such as protecting copyright; how can IP be protected during the digitalisation of the supply chain?

A challenge also lies in the implementation of additive manufacturing. Many processes are ingrained in the manufacturing sector, and change takes time because of the high degree of automation for additive manufacturing.

(Source: Logistik-Express - 3D-Druck & Logistik – Herausforderung liegt in der Umsetzung)

Clearly a time of great opportunity lies ahead for the spare parts industry; where technology plays a key role to streamlining and improving processes.

Melchers sources a wide range of mechanical, electrical, hydraulic, and pneumatic spare parts for industries such as the brewery industry.

For more information on how Melchers can help with sourcing in Europe and North America, technical clarification, support and after sales service with high qualified local engineers please contact us at: LinkedIn@melchers.de